Edge Protection System

Many safety accidents in the construction industry are related to working at heights, sometimes because of sliding debris or tools, and others because of injuries or deaths of falling people.

How to make people or objects fall to a low level has always been a concern and discussed question. With the upgrade of technology, the modified Edge Protection System can solve these core.

Edge protection systems (also called fall protection systems) are used to protect building and construction edges, technical openings (such as elevators), roof edges, passages, and other areas where there is a risk of falling from heights. problems more effectively than the traditional guardrail system.

safeguard security

All systems in accordance with EN 13374, OSHA 1926 and AS/NZS 4994

rubust and reliable

Made of 100% high-quality carbon steel, adopted mould, rust and corrosion-resisting measures

Multi-functional

Multiple parts can be flexibly combined, providing full protection for each worksite edge

simple and efficent

Distinctive modularity, faster installation design, dismantle, carry and maintaining

significant cost saving

Enhance work efficiency, shorten the time limit for projects, and lower 50% of labor costs

APAC Edge Protection System: Your #1 Choice

Starting from the beginning of originally developed concrete edge protection barriers to protect roofers working on commercial projects, as the years continued, APAC began growing with famous construction contractors, providing edge protection systems, guardrail systems, and various temporary fencing and safety netting applications for construction projects.

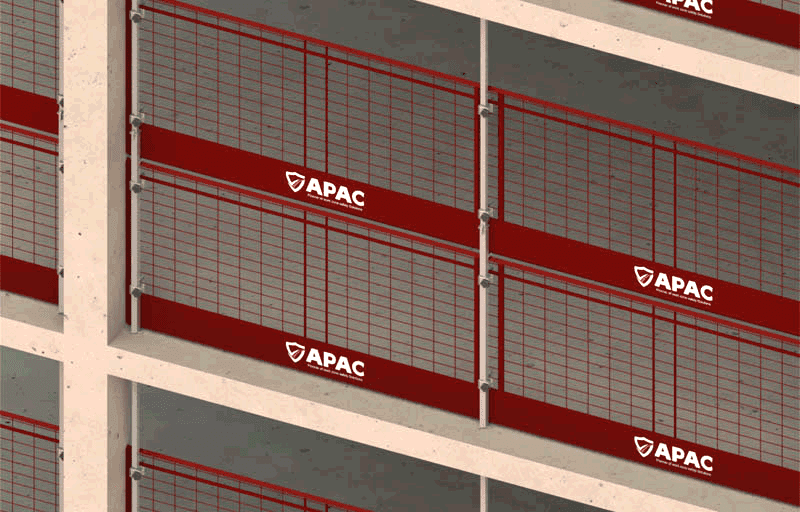

Concrete Edge Protection

We have different temporary edge protection systems that can be adapted to different concrete frames. A concrete edge protection system can be specified in a variety of ways.

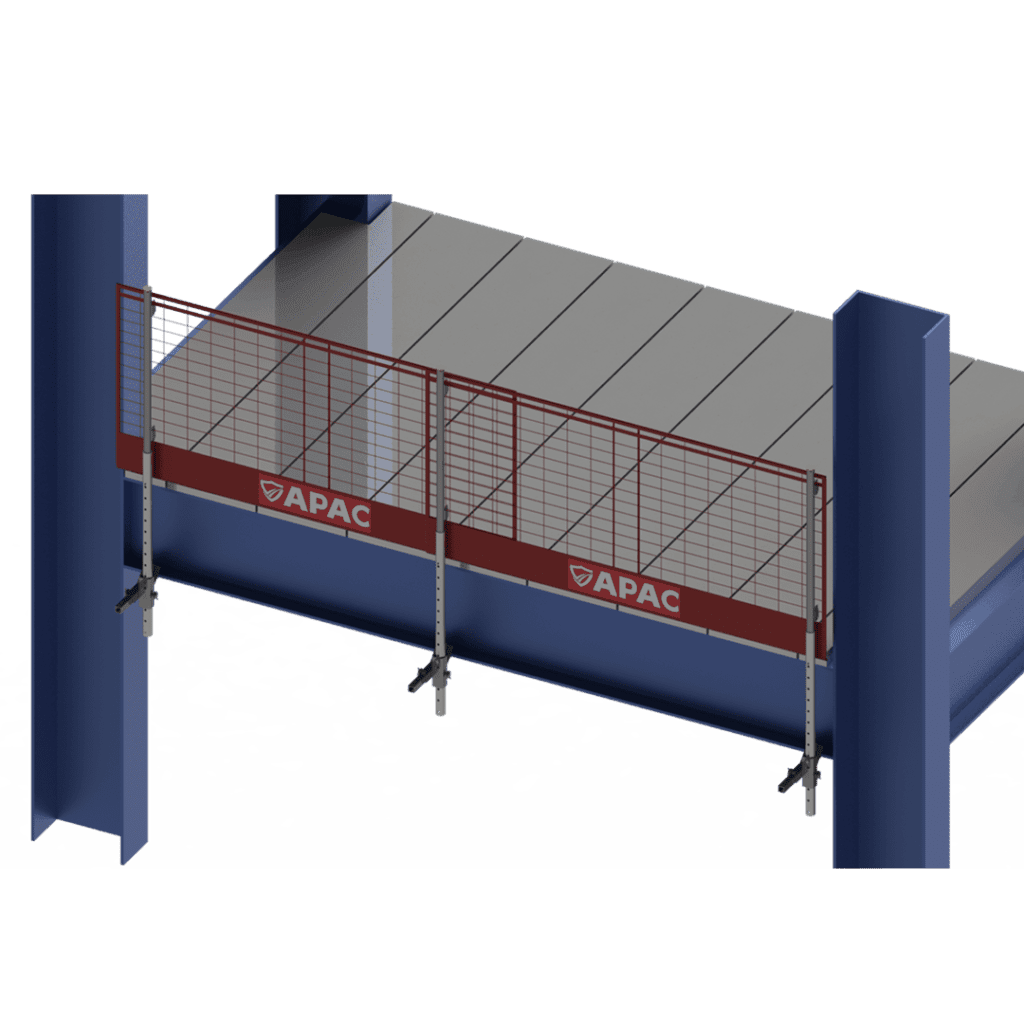

Steel Edge Protection

Steel structures require specific edge protection systems that are designed to ensure the safety of workers during construction and maintenance activities.

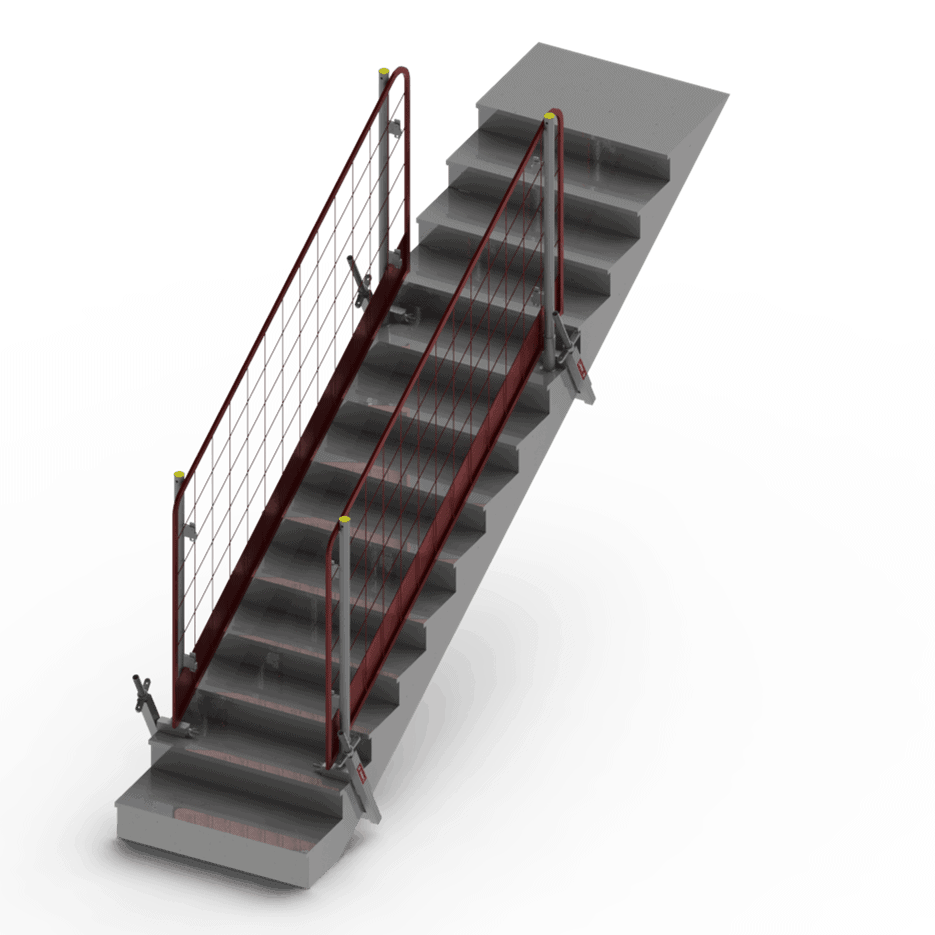

Stair Edge Protection

During the construction phase, stairs are widespread walking surfaces on construction sites. the APAC socket base stairway edge protection system protects workers when using stairs.

Formwork Edge Protection

Formwork edge protection is the installation of edge protection products on the primary or secondary beams of formwork.

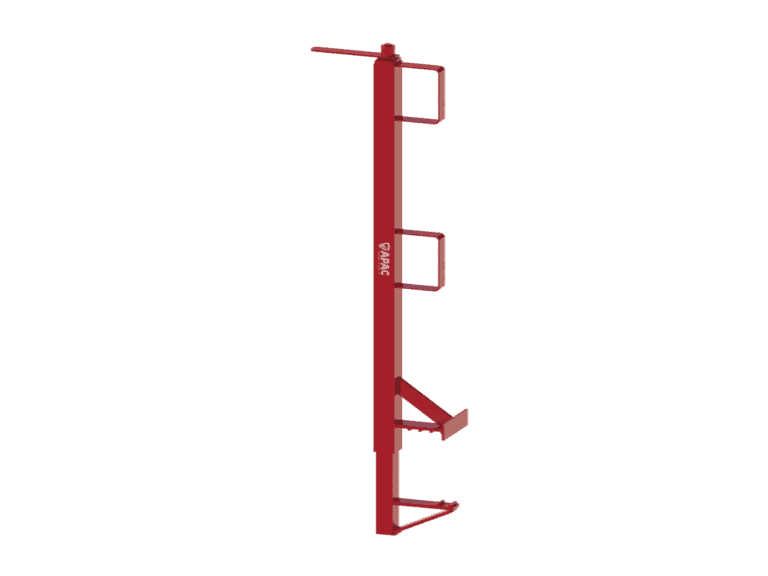

Compression post

The compression post is a collective fall protection device, that is used for securing edges between concrete slabs and other situations on construction sites.

More than just produts

Whether you are an engineer, purchase leader, product manager, or project manager, our 3D modeling is convenient to show you the product structure overviews and design concepts.

APAC has a wide range of Edge Protection Systems available.

See a snapshot of the equipment and solutions in the below catalog.

APAC provides full technical guidance for the installation of the product, we have filmed the installation and dismantlement and other operation videos. We will guide you a hand by hand to operate APAC’s edge protection system.

Your TURNKEY partner for

edge protection systems

and worksite safety equipment

Common usage scenarios of Edge Protection Systems

In addition to the above advantages that the Edge Protection System brings, it also conforms to the global strategy to maintain the sustainable development of society, about creating a better work environment, less wasted resources, and improved economic development.

More and more contractors are already using and benefiting from edge protection systems in their projects.

COMMERCIAL CONSTRUCTION

Used in commercial construction for the protection of workers from accidental falls over open edges on building sites, such as at a sidewalk or roof edge.

INDUSTRIAL CONSTRUCTION

Used to protect the edges of factories, power plants, warehouses, and other highly specialized facilities construction projects from accidental damage.

RESIDENTIAL CONSTRUCTION

Provides compliance equipment for fall protection in residential construction, preventing a construction worker from reaching the height of a fall hazard or falling over the roof edge.

INFRASTRUCTURE CONSTRUCTION

Used in infrastructure projects, designed to protect the edges of a structure from various types of impacts and hazards from the surrounding environment.

Premier Edge Protection System manufacturer

Focus on the construction Edge Protection industry for over 10 years, APAC Builders Equipment Company has been recognized as China’s leading manufacturer of quality edge protection equipment for the commercial and industrial construction market.

We have 3 bases to manufacture the entire edge protection system, and the capacity can reach up to 12,000 ㎡ daily.

We can provide not only conventional-size mesh barriers but also design and manufacture according to the protection standards of different countries and budget requirements.

We are open to your orders; whether a container volume or a bulk order, we will spare no effort to meet your most detailed requirements.

Our ordering process

1. Receive instant inquiry

You can contact our engineers directly by email or WhatsApp or write down your need on our online quoting platform. APAC engineers are fluent in English and can promptly reply to you this question.

2. Corfirm unit arrangement

Configure EPS parts specifications, and select a lead time that suits your project schedule.

Suppose you are looking for edge protection systems for flexible applications. In that case, APAC may also be ODM until you confirm the fit sample.

3. Production

We select the best manufacturer material for your order, and production begins immediately.

According to the project requirement, master the production schedule and process to complete the product within the budget.

4. Quality control

All products must go through four checks in the manufacturing process, according to the batch sampling, and the quality inspection report will be sent to you on time.

We take full responsibility for ensuring each part will be manufactured according to our quality standards.

5. Goods delivery

Individual packaging and cushioning will prevent the goods from moving randomly or hitting each other during transit. And multi-layer of plastic protective film will be wrapped around each pallet to avoid damage from moisture.

We customize the crating method based on the volume of products you order. All goods will arrive undamaged, it is indisputable.

Galley of Global Edge Protection System Projects

Open slab edges, skylight openings, construction openings, stairwells, balconies, working platforms, etc., are ideal places where you need to use edge protection systems. Edge protection systems generally create a physical barrier to protect people and objects from falling.

APAC edge protection equipment covers multi-faceted, cross-functional product lines used throughout commercial facilities and industrial plants worldwide.

Accurate customer evaluation, let your choice be more assured!

I was v pleased to cooperate with APAC.

Edge Protection | The Ultimate FAQ Guide

The FAQ guide can help to know the edge protection system and provide info for brand fresh entrants or existing competitors within the Edge Protection System industry.

1. Why should I invest in the Edge Protection System Market?

Increasing urbanization has led to a huge rise in the construction of buildings, especially the new high-rise. As a result, the urgent thing in front of construction contractors is that you need to ensure your employees and the general public keep safe and secure during construction progress. That’s why more and more construction projects use edge protection systems.

In recent years, Europe and North America have driven the increasing demand for Edge Protection Systems. With the increasing spending on the general construction industry, building retrofitting and more-intense competition, increasing adoption of Edge Protection Systems in developing countries will drive growth in the global market.

According to the research report of Dataintelo, the global Edge Protection System market is valued at 385.9 million USD in 2020 and is expected to reach 602.6 million USD by the end of 2026, at a CAGR of 11.9% during the forecast period (2021-2028).

Whether you are a construction company, or a distributor, as you see, there are lucrative opportunities in this ever-growing market.

Click here to DOWNLOAD 2021 Edge Protection System Market Search Report.

2. Are There Legal Requirements I Need To Comply With For Edge Protection System?

For works involved at heights, there are so many peoples prone to risks at every moment. So, you need to comply with different kinds of legal requirements to use the proper edge protection system to ensure their safety.

Many regulatory committees have set different sets of standard guidelines that you must follow. The European standard for temporary edge protection follows specified class standards of the edge protection systems conforming to class A and class B of EN 13374.

The Occupational Safety And Health Administration (OSHA) specifies different standards in sub-sections 1910.29 (b)(1) until 1910.29 (b)(9) for edge protection systems.

You need to follow the standards according to your local legal requirements. If you proceed with works without following the complete and proper guidelines, the regulatory committees will enforce applicable charges against your company. So, you must ensure that you comply with every legal requirement for edge protection systems.

3. What’s the difference between the guardrail system and the edge protection system for Concrete Structure?

The guardrail system is part of the formwork of deck.

So firstly you form the deck prior to concrete. That railing goes in before the concrete. Then you need to strip the deck out below and put the slab grabbers on with the 2×4 and debris netting.

With edge protection system for Concrete Structure, you actually pour the concrete, measure and mark the locations for the post foot, drill the whole, then fastener the boot into the concrete. Once the post foot is security, the post and the mesh barriers can be installed.

No tie off necessary, no one walking around. Even if the mesh barrier panels is the largest we offer, they are lightweight and easily moved into position.

All perimeter control once you get the barrier system up.

4. What’s the cost benefit analysis of edge protection system?

It’s based on your original budget, which are slab grabber 2×4, debris netting, installation, maintenance and removal.

When you purchase the edge protection system, it’s a bigger cost up front buying the posts and mesh barrier panels, buying all the hardware. So that cost was a little higher than what you typically would have.

The installation was a little quicker. So you do save money on installation.

And the real savings comes later on down the road when the maintenance comes into play in the removal.

During the installation of exterior skin, the edge protection system of Bolt Down System can stay in place, so there’s zero maintenance.

You can drop it right in the stillage when you removing the panels, just banded up, remove it and send it to the next job.

Start Your Next PROJECT with us

Related post

what you should know about edge protection systems?

Everything you need to know about edge protection systems, click the button and read more about it.

STANDARD GUIDANCE FOR TEMPORARY EDGE PROTECTION SYSTEMS

Different countries own different regulations and standards for working at height. This blog has everything that you need to know about the standards of EPS.